Types of Robotics Actuators: Explore the different types of actuators used in robotics, such as electric, hydraulic, and pneumatic actuators. Discuss their functions, advantages, and limitations in the context of robotics

Robotics has become an integral part of our daily lives, from manufacturing and healthcare to entertainment and transportation. At the heart of every robot lies a crucial component known as the actuator. An actuator is a device that converts energy into motion, allowing a robot to move and perform tasks. In this article, we will explore the different types of actuators used in robotics, their functions, advantages, and limitations.

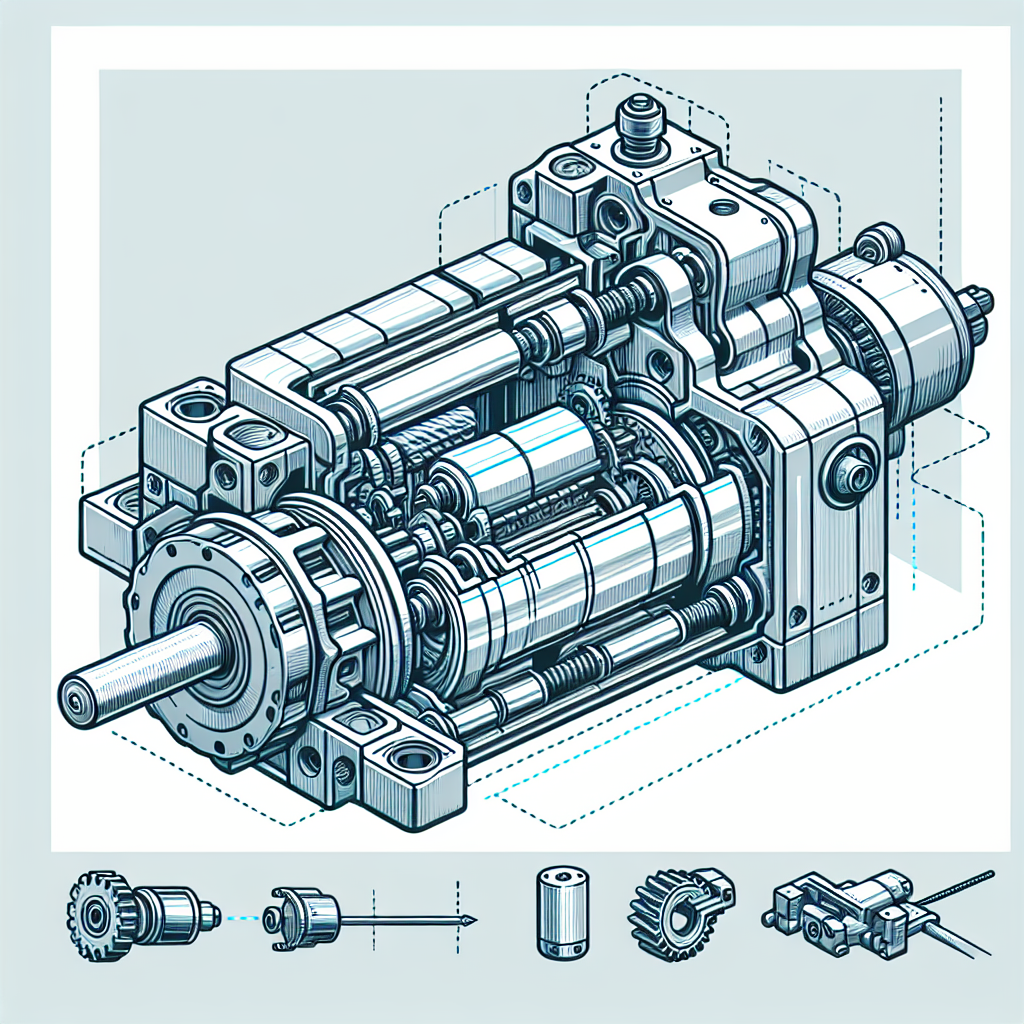

Electric actuators are the most commonly used type of actuator in robotics. They use electricity to create motion, making them ideal for precise and controlled movements. Electric actuators come in various forms, such as DC motors, stepper motors, and servo motors. DC motors are the simplest type and are commonly used in small robots. They provide continuous rotation and are relatively inexpensive. Stepper motors, on the other hand, provide precise control over the rotation of the motor shaft, making them suitable for applications that require high accuracy. Servo motors are a combination of DC and stepper motors, providing both continuous rotation and precise control. They are commonly used in robotic arms and legs.

One of the main advantages of electric actuators is their high precision and accuracy. They can be controlled with great precision, making them suitable for delicate tasks such as surgery or assembly. Electric actuators also have a high power-to-weight ratio, meaning they can produce a lot of force while remaining lightweight. This makes them ideal for use in small and agile robots. However, electric actuators also have some limitations. They require a power source, which can limit their mobility and make them less suitable for outdoor use. They also have a limited range of motion, making them less versatile compared to other types of actuators.

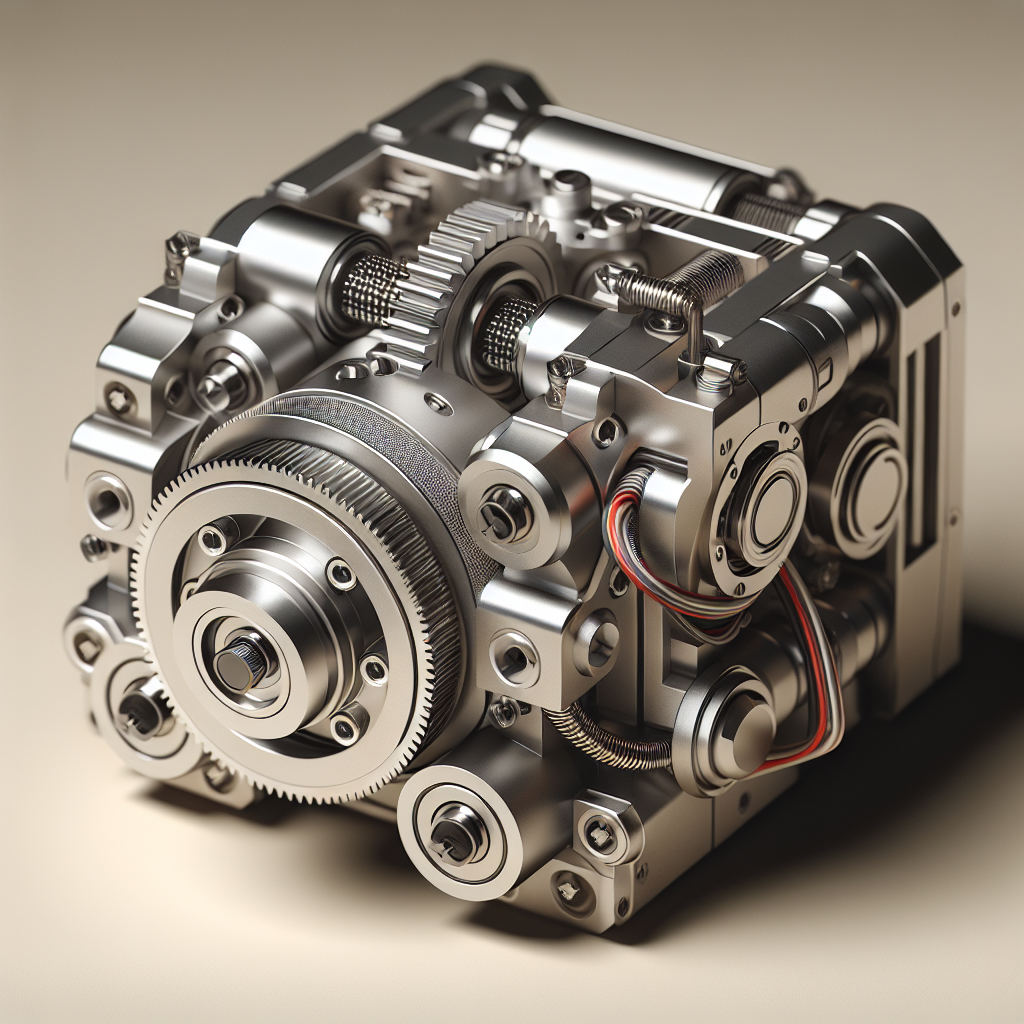

Hydraulic actuators use pressurized fluid to create motion. They are commonly used in heavy-duty applications that require a lot of force, such as construction and mining. Hydraulic actuators consist of a cylinder, a piston, and a hydraulic pump. When the pump pressurizes the fluid, it pushes the piston, creating linear motion. The main advantage of hydraulic actuators is their ability to produce a lot of force. They are also highly durable and can withstand harsh environments. However, they are bulky and heavy, making them less suitable for small and agile robots. They also require a complex system of pumps, valves, and hoses, making them more expensive and difficult to maintain.

Pneumatic actuators use compressed air to create motion. They are similar to hydraulic actuators, but instead of using fluid, they use air. Pneumatic actuators are commonly used in industrial robots for tasks such as gripping and lifting. They are also used in pneumatic cylinders, which provide linear motion. The main advantage of pneumatic actuators is their low cost and simplicity. They are also lightweight and can produce a lot of force, making them suitable for a wide range of applications. However, they are not as precise as electric actuators and can be affected by changes in air pressure, making them less suitable for delicate tasks.

In conclusion, robotics actuators play a crucial role in the functioning of robots. Electric actuators are the most commonly used type, providing high precision and accuracy. Hydraulic actuators are ideal for heavy-duty applications, while pneumatic actuators are cost-effective and versatile. Each type of actuator has its own advantages and limitations, and the choice of actuator depends on the specific needs of the robot. As technology continues to advance, we can expect to see even more innovative and efficient types of actuators being developed for use in robotics.

Importance of Robotics Actuators: Highlight the crucial role that actuators play in the functioning of robots. Discuss how they are responsible for converting electrical or mechanical signals into physical movement, and how they enable robots to perform various tasks

Robotics has become an integral part of our daily lives, from manufacturing industries to healthcare and even in our homes. These intelligent machines are designed to perform tasks that are either too dangerous or too tedious for humans. But have you ever wondered how these robots are able to move and perform tasks with such precision and accuracy? The answer lies in the crucial role of robotics actuators.

Actuators are the components responsible for converting electrical or mechanical signals into physical movement. They are essentially the muscles of a robot, enabling it to move, grip, and perform various tasks. Without actuators, robots would be nothing more than stationary machines.

One of the most common types of actuators used in robotics is the electric motor. These motors are responsible for converting electrical energy into mechanical energy, which is then used to move the robot’s joints and limbs. The movement of these joints and limbs is what allows the robot to perform tasks such as picking up objects, walking, or even dancing.

But it’s not just electric motors that are used as actuators in robotics. Hydraulic and pneumatic actuators are also commonly used, especially in larger and more heavy-duty robots. These actuators use pressurized fluids to create movement, making them ideal for tasks that require a lot of force, such as lifting heavy objects.

The importance of robotics actuators can be seen in the wide range of tasks that robots are able to perform. From simple repetitive tasks in manufacturing to complex surgeries in healthcare, actuators play a crucial role in the functioning of robots. They are what make robots versatile and adaptable, able to perform a variety of tasks with precision and speed.

One of the key advantages of using actuators in robotics is their ability to provide precise and repeatable movements. Unlike humans, who may make slight errors or tire out over time, actuators are able to consistently perform tasks with the same level of accuracy. This makes them ideal for tasks that require precision, such as surgery or assembly line work.

Moreover, robotics actuators are also able to work in harsh environments that may be dangerous or inaccessible to humans. For example, robots equipped with hydraulic actuators can be used in deep-sea exploration or in disaster zones where it may be too dangerous for humans to enter. This not only protects human lives but also allows for tasks to be completed more efficiently and effectively.

In addition to their physical capabilities, robotics actuators also play a crucial role in the intelligence of robots. By receiving signals from sensors and processing them, actuators are able to adjust their movements accordingly. This allows robots to adapt to changing environments and perform tasks with more precision and efficiency.

The advancements in robotics actuators have also led to the development of more advanced and sophisticated robots. For example, soft actuators, which are made of flexible materials, are being used to create robots that can mimic the movements and dexterity of human muscles. This has opened up new possibilities in fields such as prosthetics and rehabilitation.

In conclusion, robotics actuators are the backbone of any robot, enabling it to move, perform tasks, and adapt to its environment. They are responsible for converting electrical or mechanical signals into physical movement, making robots versatile and adaptable. As technology continues to advance, we can expect to see even more advanced and intelligent robots, thanks to the crucial role of robotics actuators.

Advancements in Robotics Actuators: Discuss the latest advancements in robotics actuators, such as the development of smart actuators and the use of artificial intelligence and machine learning in actuator technology. Explore how these advancements are shaping the future of robotics

Robotics has come a long way since its inception, with advancements in technology constantly pushing the boundaries of what is possible. One of the key components of a robot is its actuator, which is responsible for converting energy into motion. In simple terms, an actuator is the muscle of a robot, allowing it to move and perform tasks. Over the years, there have been significant advancements in robotics actuators, with the latest developments being the development of smart actuators and the integration of artificial intelligence and machine learning in actuator technology.

Smart actuators are a relatively new concept in the world of robotics. These actuators are equipped with sensors and microprocessors, allowing them to gather and process data in real-time. This data can then be used to make decisions and adjust the actuator’s movements accordingly. This level of intelligence in actuators has opened up a whole new realm of possibilities for robots. They can now adapt to changing environments and perform tasks with greater precision and efficiency.

One of the key benefits of smart actuators is their ability to self-monitor and self-correct. This means that they can detect any issues or malfunctions and make adjustments to ensure optimal performance. This not only saves time and resources but also increases the overall reliability of the robot. In industries where robots are used for critical tasks, such as manufacturing or healthcare, this level of reliability is crucial.

Another significant advancement in robotics actuators is the integration of artificial intelligence (AI) and machine learning (ML) technology. AI and ML have revolutionized the way robots operate, allowing them to learn and adapt to their surroundings. By using algorithms and data, robots can now make decisions and perform tasks without human intervention. This has greatly increased the autonomy of robots, making them more efficient and versatile.

One of the most notable applications of AI and ML in actuator technology is in the field of prosthetics. With the use of advanced actuators, AI, and ML, prosthetic limbs can now mimic the movements of natural limbs, providing a more natural and fluid motion for the user. This has greatly improved the quality of life for individuals with limb loss, allowing them to perform daily tasks with greater ease and confidence.

In addition to prosthetics, AI and ML are also being used in the development of humanoid robots. These robots are designed to resemble and mimic human movements, making them more relatable and easier to interact with. With the use of advanced actuators and AI, these robots can now perform complex tasks, such as walking, running, and even dancing. This has opened up a whole new world of possibilities for robots, with potential applications in industries such as entertainment, healthcare, and education.

The integration of AI and ML in actuator technology has also led to the development of collaborative robots, also known as cobots. These robots are designed to work alongside humans, assisting them in tasks that are either too dangerous or too tedious for humans to perform. With the use of advanced actuators, cobots can now sense and respond to human movements, making them safer and more efficient to work with.

In conclusion, the advancements in robotics actuators, particularly the development of smart actuators and the integration of AI and ML, have greatly improved the capabilities and potential applications of robots. With these advancements, robots are becoming more intelligent, autonomous, and versatile, shaping the future of robotics in various industries. As technology continues to evolve, we can only expect to see further advancements in robotics actuators, leading to even more groundbreaking developments in the field of robotics.